PP Woven Bags have become increasingly popular in the packaging industry. They are made from polypropylene, a versatile plastic material. This type of bag offers significant advantages for various applications.

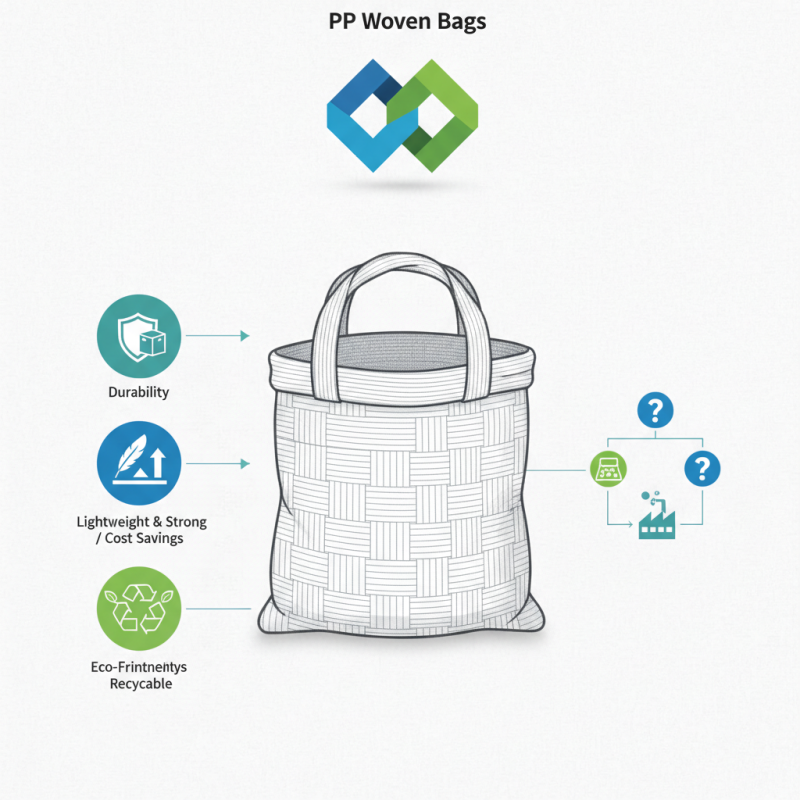

One key benefit of the PP Woven Bag is its durability. These bags can endure harsh handling and heavy loads. They resist tearing, making them ideal for transporting goods. In addition, they are lightweight yet strong, which can lead to cost savings in shipping.

Another aspect to consider is their eco-friendliness. Many manufacturers now focus on making these bags recyclable. However, not all PP Woven Bags are created equal. Some may still end up in landfills. Continuous improvement and awareness are needed to enhance their environmental impact. Choosing the right PP Woven Bag involves weighing these factors carefully.

PP woven bags are made from polypropylene, a versatile plastic. They are woven into a sturdy fabric, creating a durable structure. These bags are used widely in various industries for packaging needs. Their strength comes from the weaving process, providing resistance against wear and tear.

One benefit of PP woven bags is their lightweight nature. They are easy to carry and handle. This feature makes them popular for transporting goods. Additionally, they are water-resistant, which protects contents from moisture. Many businesses favor them for bulk packaging. The breathable material helps prevent spoilage, especially in agricultural settings.

However, not all PP woven bags are the same. Some may lack the necessary strength for heavy items. It's essential to choose the right type based on specific needs. Feedback from users can help improve bag design. Despite their popularity, there still are areas for innovation and improvement. Finding ways to enhance their sustainability could make them even better for the environment.

PP woven bags are increasingly popular in the packaging industry due to their durability and versatility. The primary material used in these bags is polypropylene, a thermoplastic polymer. This material is known for its high tensile strength and resistance to abrasion. According to industry reports, the global polypropylene market is projected to reach over 100 million tons by 2025, highlighting its growing relevance.

Another important aspect is the production process. This involves weaving polypropylene fibers into a sturdy fabric. This fabric can be coated or laminated, enhancing its waterproof properties. A study indicated that PP woven bags can reduce packaging waste by up to 30%. However, this data raises questions about recycling challenges since many consumers still lack proper disposal methods.

Despite their benefits, there are areas needing improvement. The manufacturing process requires significant energy. Additionally, some consumers remain unaware of proper recycling practices. As the industry evolves, addressing these shortcomings could enhance the sustainability of PP woven bags. Progress is essential for a greener future.

PP woven bags, made from polypropylene, offer diverse benefits for packaging across industries. These bags are known for their strength and durability. According to a recent industry report, the global market for PP woven bags is projected to reach 5.1 billion USD by 2027. Their resistance to moisture and abrasion makes them suitable for transporting various products, including grains and fertilizers.

One notable advantage is their recyclability. Around 30% of PP woven bags can be recycled, contributing to sustainability efforts. The lightweight nature of these bags also reduces shipping costs. However, some challenges exist. For instance, if not properly recycled, they can lead to environmental pollution. Moreover, manufacturers must ensure consistent quality to maintain customer trust, as poorly made bags may not withstand heavy loads.

In agricultural applications, these bags can enhance product visibility while providing adequate protection. An estimated 60% of farmers have reported improved crop yields using PP woven bags for storage. Yet, awareness of recycling practices is still limited. Educating end-users on responsible disposal is crucial to maximizing the benefits of these bags while minimizing their environmental impact.

PP woven bags have gained traction across various industries, thanks to their strength and versatility. In the agricultural sector, they are commonly used to package grains, fertilizers, and seeds. According to a recent report by the Global Biodegradable Plastic Market, the agricultural application segment is projected to grow significantly. This growth is mainly due to the increasing demand for durable packaging solutions.

In addition to agriculture, construction companies favor PP woven bags for cement and sand packaging. These bags are popular because they can withstand heavy loads. A study from the Packaging Industry Association highlighted that over 45% of construction materials are now transported in PP woven bags. This shift not only supports material safety but also decreases transportation costs.

The food industry also benefits from PP woven bags, especially in bulk packaging. They are moisture-resistant and help to keep products fresh. However, some drawbacks exist. Not all PP bags are recyclable, which raises environmental concerns. Companies are now focusing on producing more eco-friendly options. While PP woven bags offer many advantages, their long-term environmental impact requires continuous evaluation.

PP woven bags have gained popularity in the packaging industry. They are made from polypropylene and offer durability, flexibility, and water resistance. A comparative analysis reveals how they stack up against traditional packaging options like paper and plastic bags.

PP woven bags weigh less than paper bags. This can significantly reduce shipping costs. According to industry reports, businesses can save up to 30% on transportation expenses when switching to PP woven bags. They are reusable and recyclable, offering a better life cycle compared to single-use plastic. However, some consumers still perceive them as less eco-friendly than biodegradable options.

Tip: When choosing packaging, consider the entire supply chain. Evaluate your environmental footprint.

PP woven bags are also resistant to punctures and tears. This ensures contents remain secure. While they excel in many areas, some drawbacks exist. They may not be as easily compostable as other materials. Using them effectively requires a balance between durability and environmental impact.

Tip: Educate your team about the best practices for recycling PP woven bags. Understanding their properties can help maximize sustainability efforts.